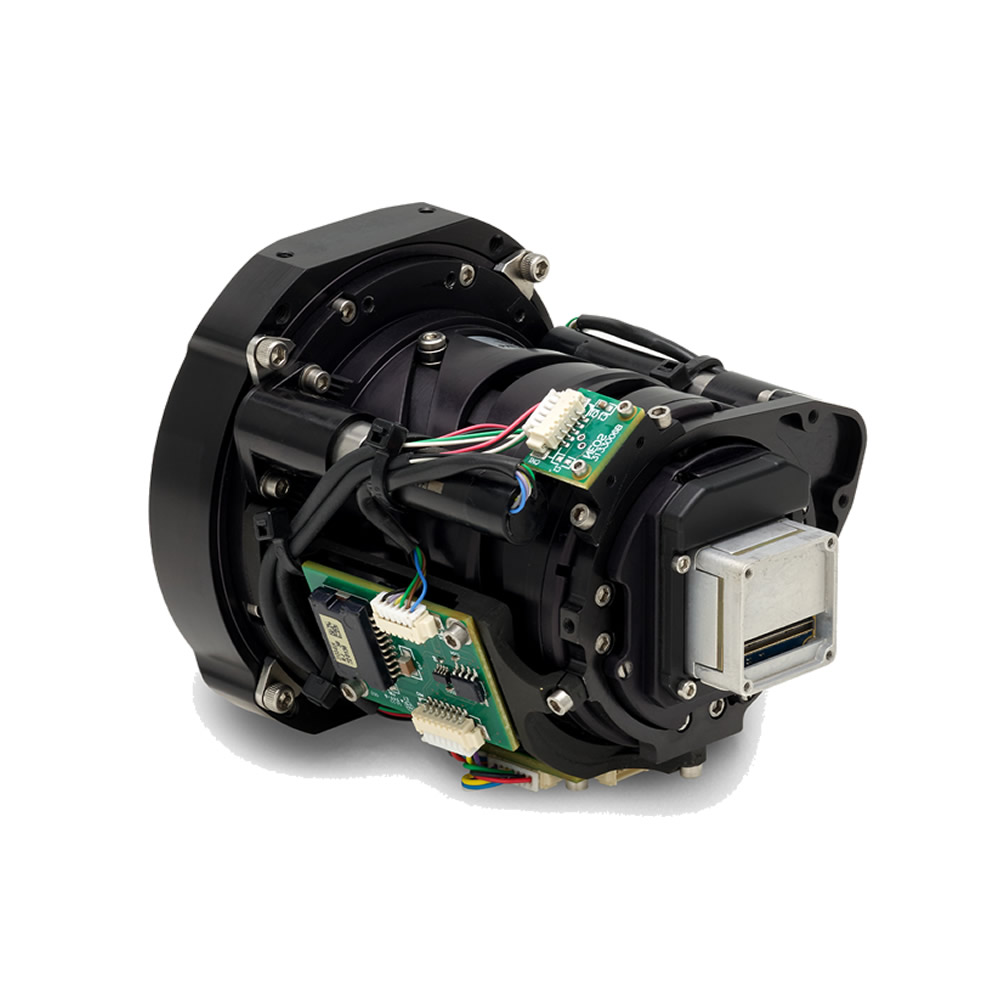

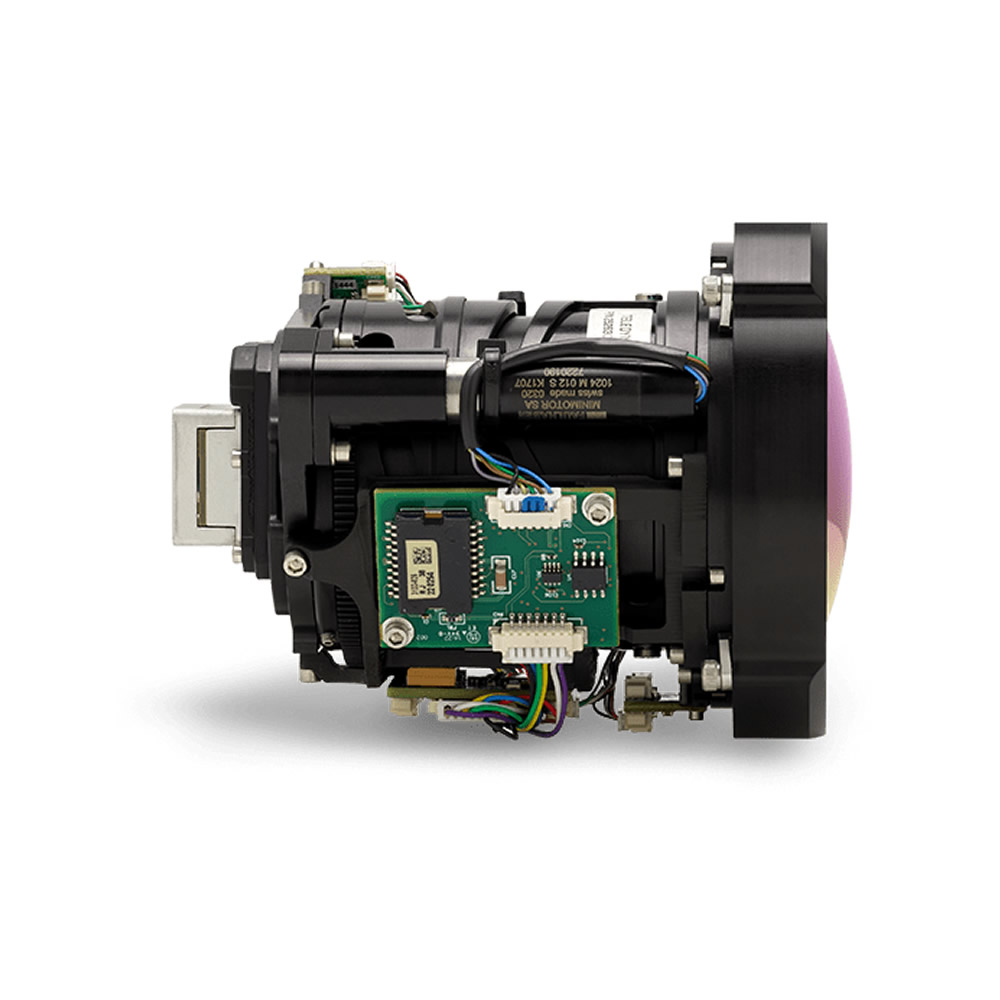

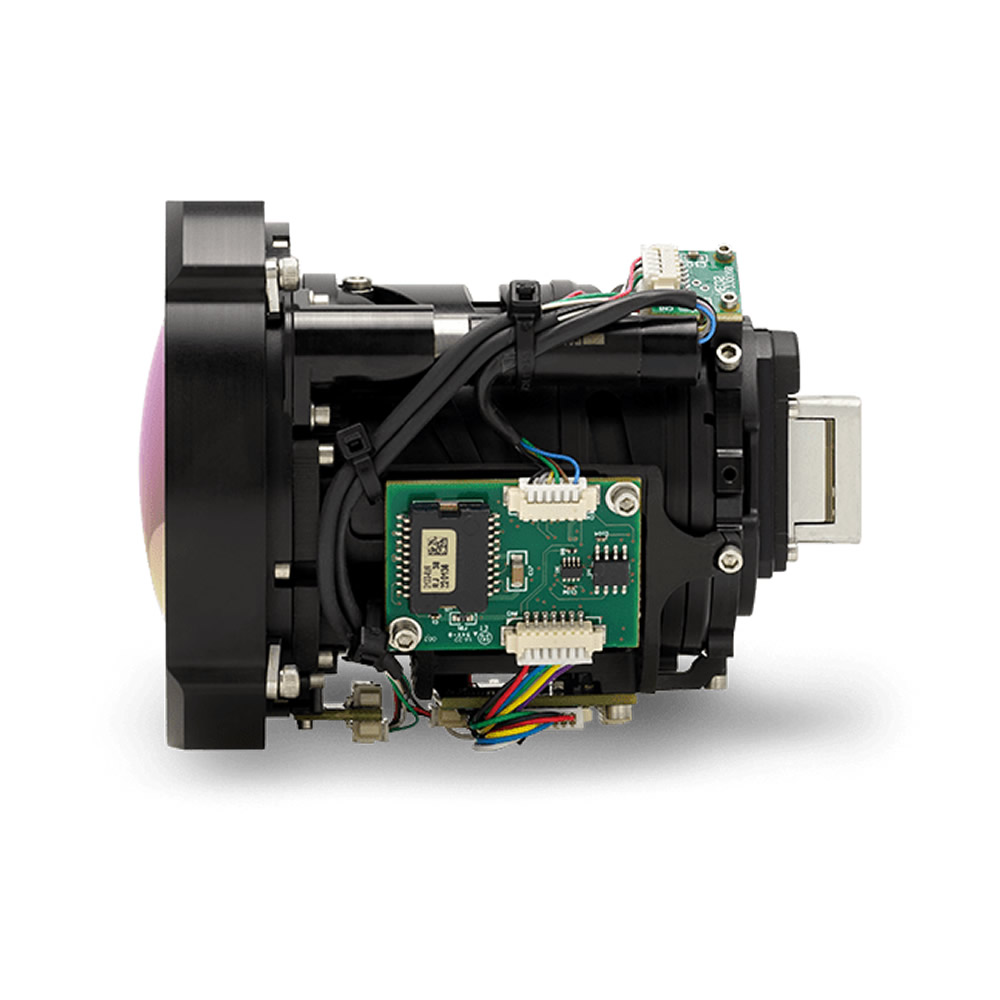

Teledyne FLIR Boson+ CZ 14-75 High Performance, Uncooled, LWIR OEM Thermal Camera Module

- 640 x 512 resolution, 12 μm pixel pitch

- LWIR microbolometer

- <20 mK thermal sensitivity

- Rugged construction with an operating temperature rating of -40 °C to 80 °C

- Upgraded AGC provides blacker blacks and whiter whites

Interfaces and Accessories sold separately.

Boson®+ CZ 14-75

High Performance, Uncooled, Longwave Infrared (LWIR) OEM Thermal Camera Module

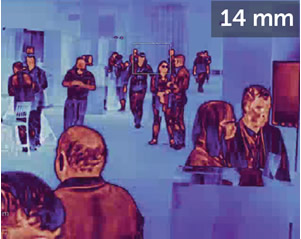

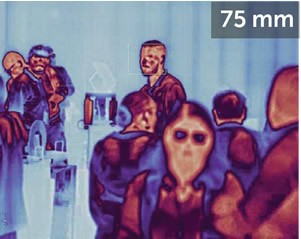

Made in the USA, the Boson+ CZ 14-75 combines Teledyne FLIR’s Boson+ world-class longwave infrared (LWIR) OEM camera module and 5x continuous zoom (CZ) lens offering a high–performance imaging solution. It features an industry-leading thermal sensitivity of ≤20 mK and an upgraded automatic gain control (AGC) filter delivering dramatically enhanced scene contrast and sharpness. The high-performance lens and control electronics maintain focus through zoom and provide real-time thermal gradient compensation as well as flexibility for user-defined command syntax and expansion for additional features.

The Boson+ camera module and 14 mm to 75 mm CZ lens are designed for each other, providing optimal performance and a single system warranty only achievable from a single source. The factory-integrated system lowers development and manufacturing risk and improves time-to-market, making the reliable Boson+ CZ 14-75 ideal for unmanned aerial vehicles, perimeter surveillance, light armored vehicle situational awareness and targeting, and soldier sighting systems.

MARKET-LEADING THERMAL SENSITIVITY, CONTRAST, AND LATENCY

NEDT of ≤20 mK extends detection, recognition, and identification (DRI) performance

- 640×512 resolution, 12 μm pixel pitch LWIR microbolometer

- ≤20 mK thermal sensitivity

- Rugged construction with an operating temperature rating of -40 °C to 80 °C

- Upgraded AGC provides blacker blacks and whiter whites

SEAMLESS OPTOMECHANICAL INTEGRATION

Camera and lens factory-designed to optimize performance and cost

- Factory alignment eliminates boresight wander through zoom

- Calibrated for maximum performance and MTF

- Object focus range compensation for near targets

- Thermal gradient compensation provides focus through full temperature range

DESIGNED FOR INTEGRATORS

Advanced control electronics, hardware, and integration support simplify integration and maximize reliability

- USB, CMOS, and MIPI video output interfaces

- Flexible user-defined command aliases

- Built-in Test (BIT) provides real-time feedback

- Manufactured in the USA, dual use, and classified under US Department of Commerce jurisdiction as EAR 6A003.b.4.a

| Focal Length | |

|---|---|

| Non-Operating Temperature Range | |

| Frame Rate Option | |

| Weight | |

| Control Channels | |

| Size | |

| Design and Construction | |

| Distortion | |

| Boresight Drift Through Zoom | |

| Peripheral Channels | |

| Image Orientation | |

| Non-Uniformity Correction (NUC) |

Factory calibrated; updated FFCs with FLIR’s Silent Shutterless NUC (SSN™) |

| Operational Altitude |

12 km (max altitude of a commercial airliner or airborne platform) |

| Operating Temperature | |

| Serial Communication | |

| ESS Thermal | |

| Scene Dynamic Range | |

| Focus Change Time | |

| Video Channels | |

| ESS Vibration | |

| FOV Change Time | |

| Focus Over Temperature | |

| Solar protection | |

| IP Rating [At Front of Lens] | |

| Lens Window Transmittance |

HEAR L1: >/= 84% for band 8-12 mmDLC L1: >/= 78% for band 8-12 mm |

| Pixel Pitch | |

| Parfocality |

At 20 °C the lens shall stay in focus thru zoom within 1/4-wave at 10.6µm |

| Shock |

9G with 11msec half-sine pulse, minimum 3 pulses for each of 3 axes |

| f-number | |

| Pixel Size | |

| Minimum Focus Distance | |

| Relative illumination | |

| Thermal Sensitvity [NETD] | |

| Symbology |

Re-writable each frame; alpha blending for translucent overlay |

| Power Supply | |

| Boson Grade Option |

Professional Grade <30 mK NEDT, Industrial Grade <20 mK NEDT |

| Front Optic Sealing |